- 1,0 – 15,0 m³/h

- Conventional control

Usage

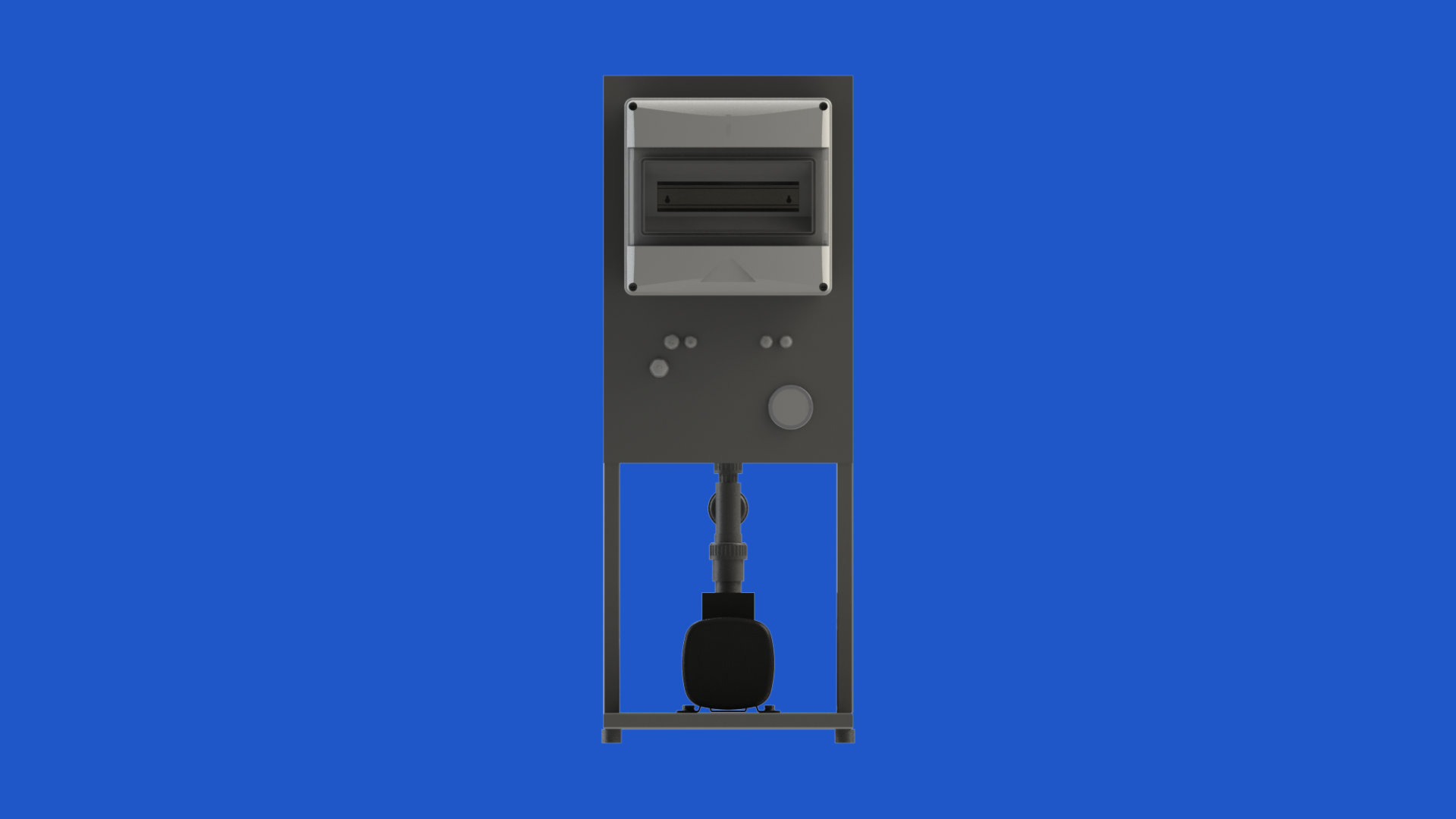

The pressure booster stations in the PEP series are single pressure booster stations with a vertical, multi-stage high-pressure centrifugal pump. The pressure booster stations are suitable for pumping service water or fully desalinated water without abrasive components. The units are factory-assembled and electrically wired ready to plug in. A diaphragm expansion tank limits the number of switching cycles and ensures pressure-dependent switching on and off without pressure surges. The high-quality stainless steel centrifugal pump in industrial design guarantees many years of reliable operation. The delivery pressure is measured by an industrial pressure sensor. The sequence control is implemented by means of a small PLC with integrated LC display.

The units can either be installed directly as a stand-alone solution or used in conjunction with the extensive range of accessories. This allows optimal adaptation to the respective requirements.

The pressure boosting stations are used where pressure boosting with pressure hysteresis is possible.

- Pumping water from storage tanks

- Pressure increase in tap water networks

- Pumping water from network separation tanks

Functionality

The pressure booster stations are designed for inflow operation with and without pre-pressure, as well as for suction operation with moderate suction height. A fully automatic, pressure-dependent control system regulates the switching on and off of the pump. Smaller withdrawal quantities are fed into the network from the diaphragm expansion tank, which prevents the pump from starting up too frequently. The pressure booster station must be protected against dry running by means of a suitable protective device (accessory). The dry running protection can be designed as a float switch, pressure switch, or electrode relay.

A collective fault signal can be tapped at the control system (potential-free changeover contact).

The pressure booster stations are electrically wired at the factory. The operating voltage is 400 V/N/PE, the control unit is operated with low voltage (24 VDC). The pressure limits and the pre-pressure in the diaphragm expansion vessel may need to be adjusted to suit local operating conditions. The factory setting is indicated on the type plate.

Advantages

Easy to use

Clear arrangement of the controls

Shut-off valves on suction and pressure side

Piping made of corrosion-resistant PVC-U

High-quality pump technology from the global market leader

Space-saving design

Stainless steel frame

Pressure sensor for actual value measurement

Sequence control using LOGO! logic module

Scope of delivery

Stainless steel centrifugal pump

Stainless steel frame

Control unit LOGO! logic module, power unit with motor protection, indicator lights, and main switch

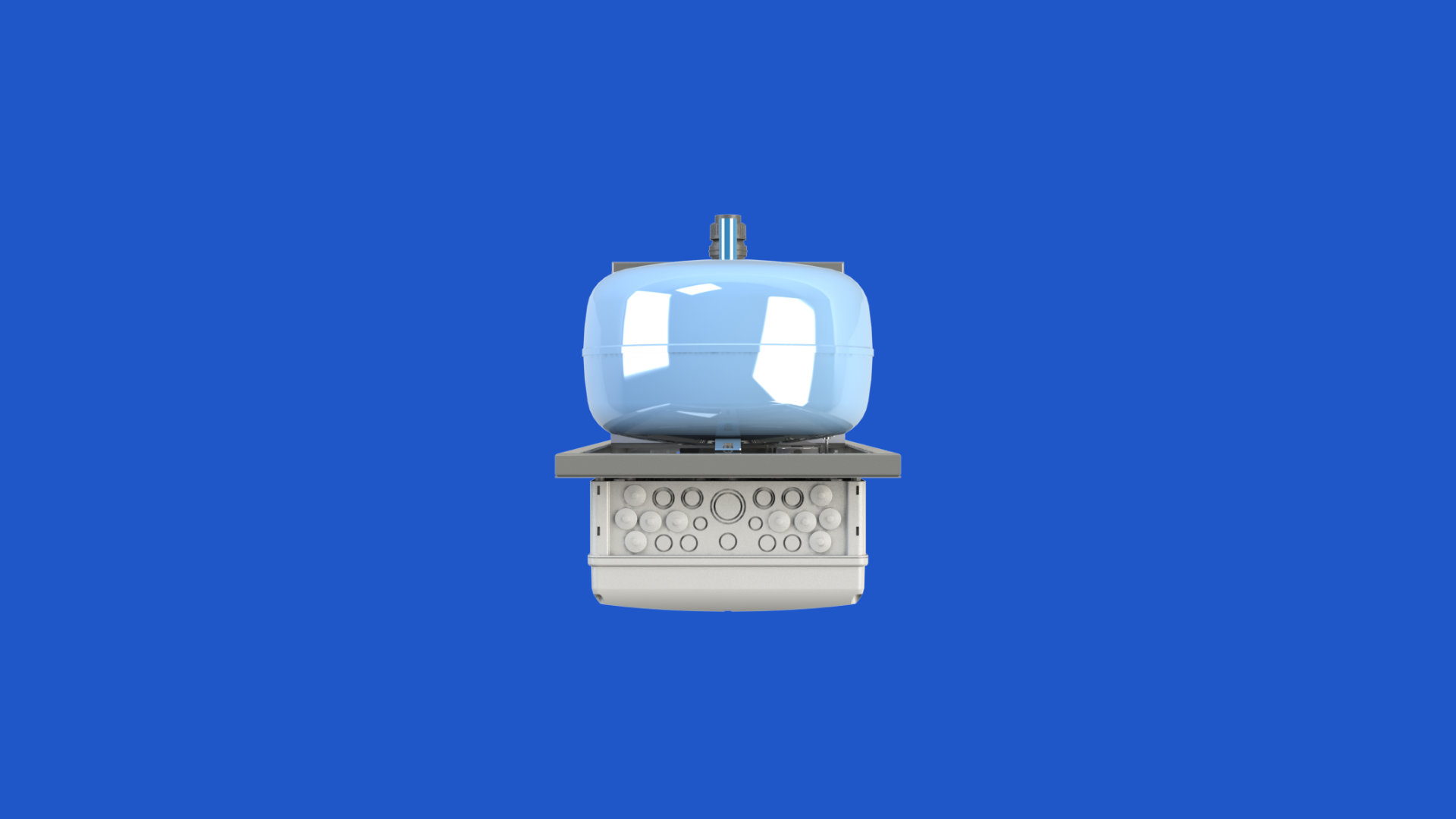

Diaphragm expansion tank

Pressure sensor

PVC-U piping, with all necessary check valves and shut-off valves

Downloads

Catalog sheet

Download