- 90 l/h – 450 l/h

Usage

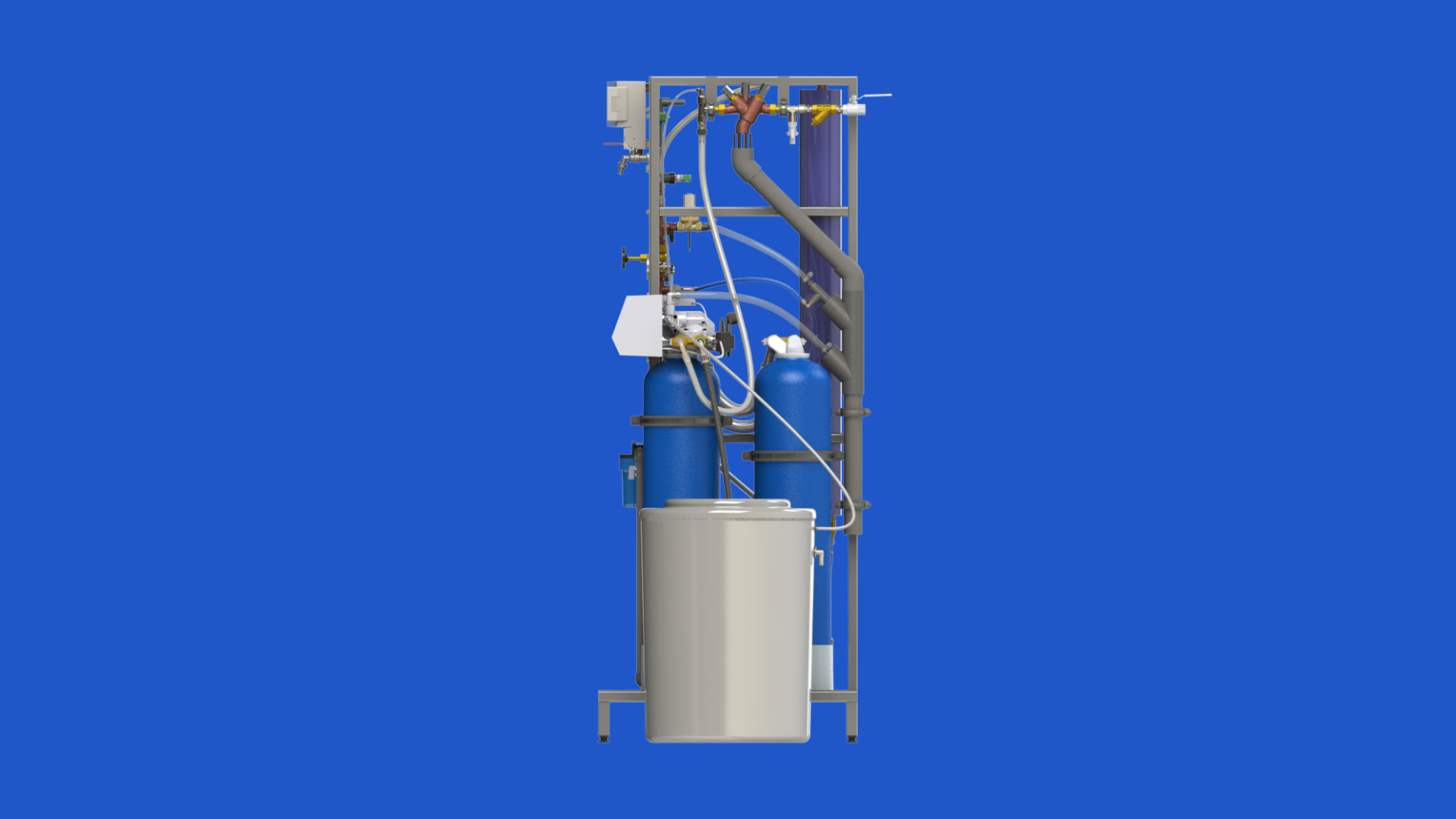

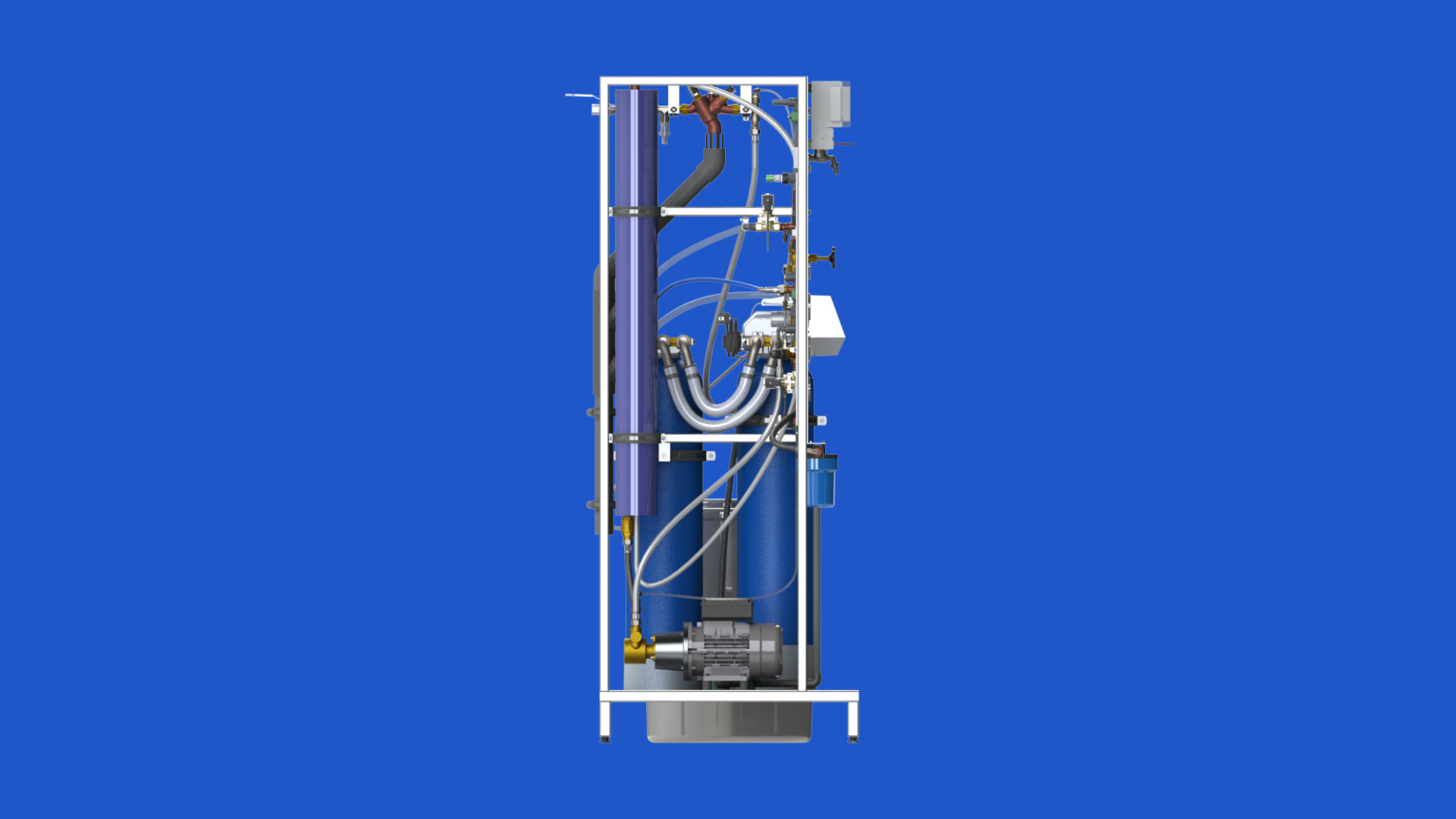

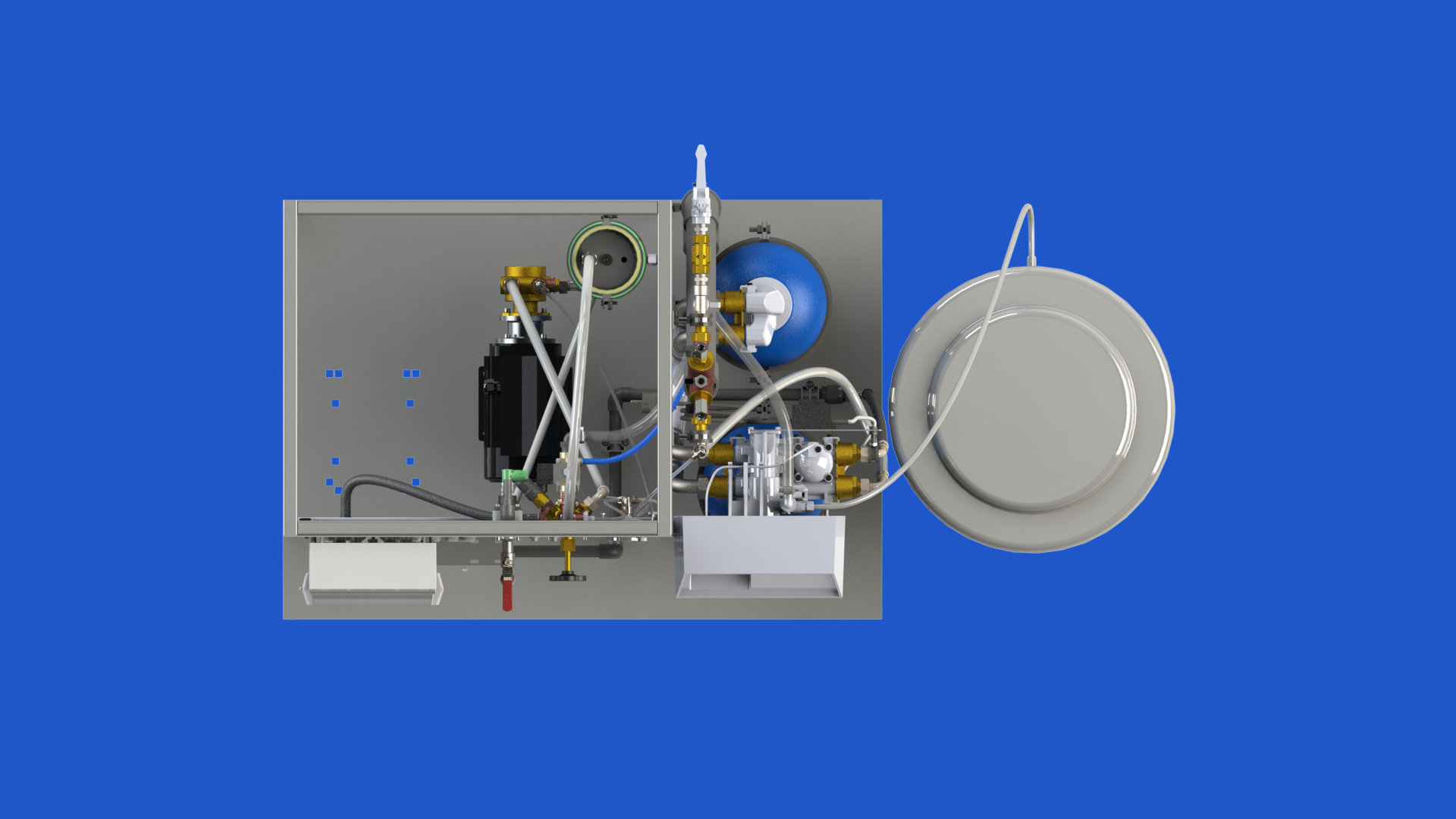

The reverse osmosis systems in the UOC series are fully pre-assembled systems for softening and subsequently desalinating drinking water or well water to drinking water quality.

The UOC systems can be used in a wide range of applications:

- Boiler feed water treatment

- Drinking water treatment for the beverage industry (brewing water, fruit juice dilution)

- Cooling water treatment

- Commercial dishwashing technology

- Laboratories

- Removal of nitrate from drinking water

- Air conditioning technology

- Car washes

- Parts cleaning systems

Another important application is the use of reverse osmosis systems as “pre-desalination systems” upstream of conventional full desalination systems. This significantly reduces the frequency of regeneration of the full desalination system and thus its operating costs.

Functionality

The raw water is first softened by ion exchange (neutral exchange) in the softening plant. Desalination then takes place in the reverse osmosis plant. The desalination process is based on a membrane diffusion process in which pure water passes through a semi-permeable membrane under high pressure and salts, colloids, and other substances are retained by the membrane. The water fed into the reverse osmosis plant is divided into a pure water volume flow (permeate) and a waste water volume flow (concentrate). The permeate is temporarily stored in unpressurized or pressurized water storage tanks to cover peak consumption. The proportion of the concentrate volume flow fed to the wastewater must not fall below a certain minimum, as this can lead to deposits (scaling or fouling) on the membrane surface and a associated drop in system performance. To improve efficiency, the other portion of the concentrate volume flow is returned to the pump and passed through the membrane again together with the fresh water volume flow.

Advantages

Fully automatic, water meter-controlled water softening system, optionally single or double softening system

Environmentally friendly desalination process

Fully automatic operation

Low maintenance and servicing requirements

Space-saving design

Low operating costs

Lowest installation costs thanks to ready-to-connect pre-assembly of all components

High-quality microprocessor control in industrial design with automatic flushing programs

Temperature-compensated conductivity measurement

Aperture control for safe operation

Shutdown options when conductivity exceeds or falls below specified limits

Including flush solenoid valve

GfK pressure pipes with leak-proof connection technology

High-quality reverse osmosis modules and components (brand-name products)

No plug-in fittings

Scope of delivery

Ready-to-connect, pre-assembled system technology, consisting of:

Stainless steel frame for mounting the water softener, reverse osmosis system, and pressure booster (accessory)

Raw water inlet assembly with shut-off valve, prefilter, and system separator

Single (UOC-E) or double water softener (UOC-D) with MP control and salt dissolving tank with sieve bottom

Reverse osmosis system with inlet assembly with sampling valve and pre-filtration, isolation valve pump, control assembly with orifice control and flush solenoid valve, flow sensor for determining the amount of permeate produced

Permeate pressure booster system (accessory)

Hardness control device Sensor test (accessory)

Hardness testing equipment

Downloads

Catalog sheet

Download