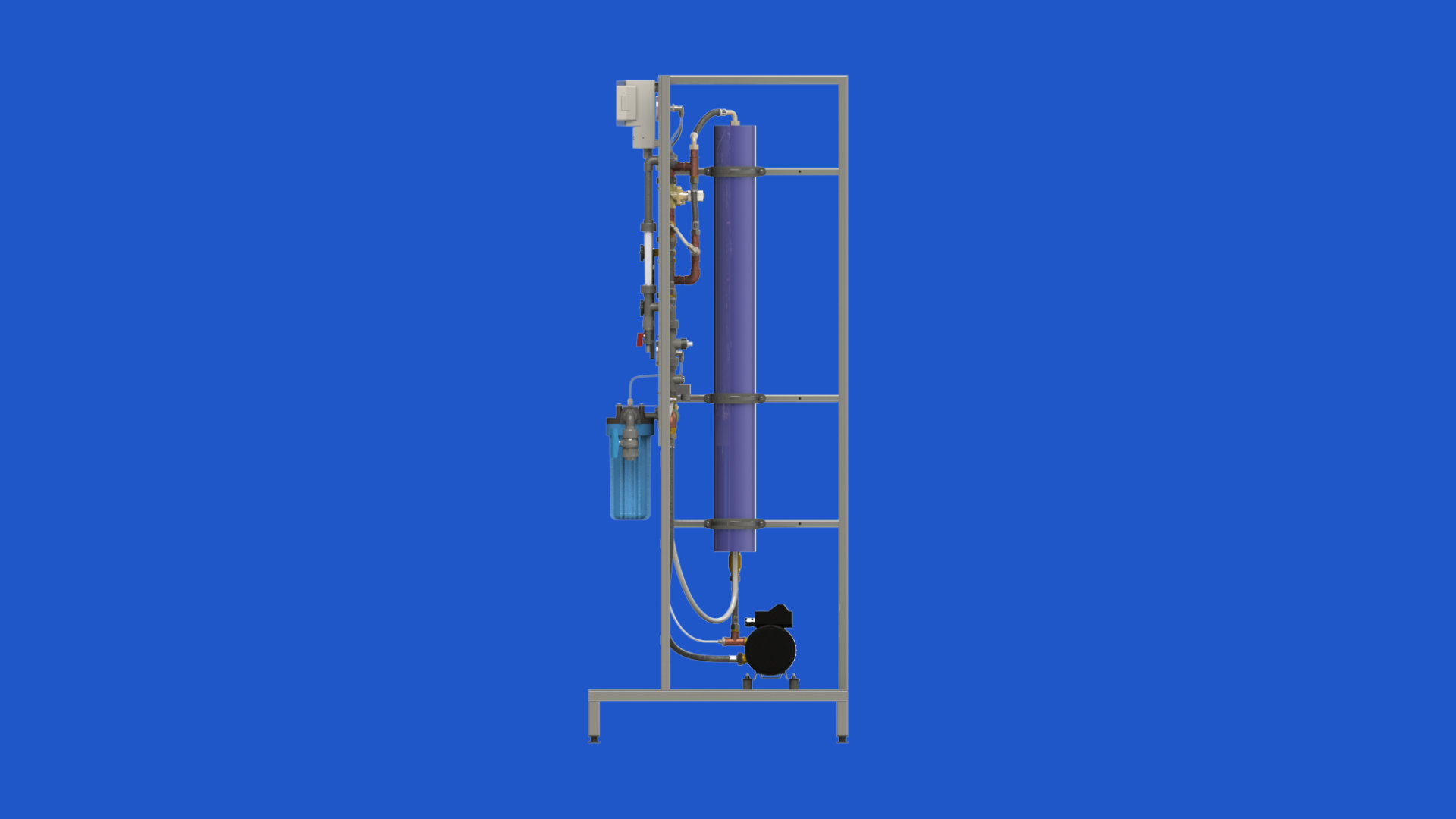

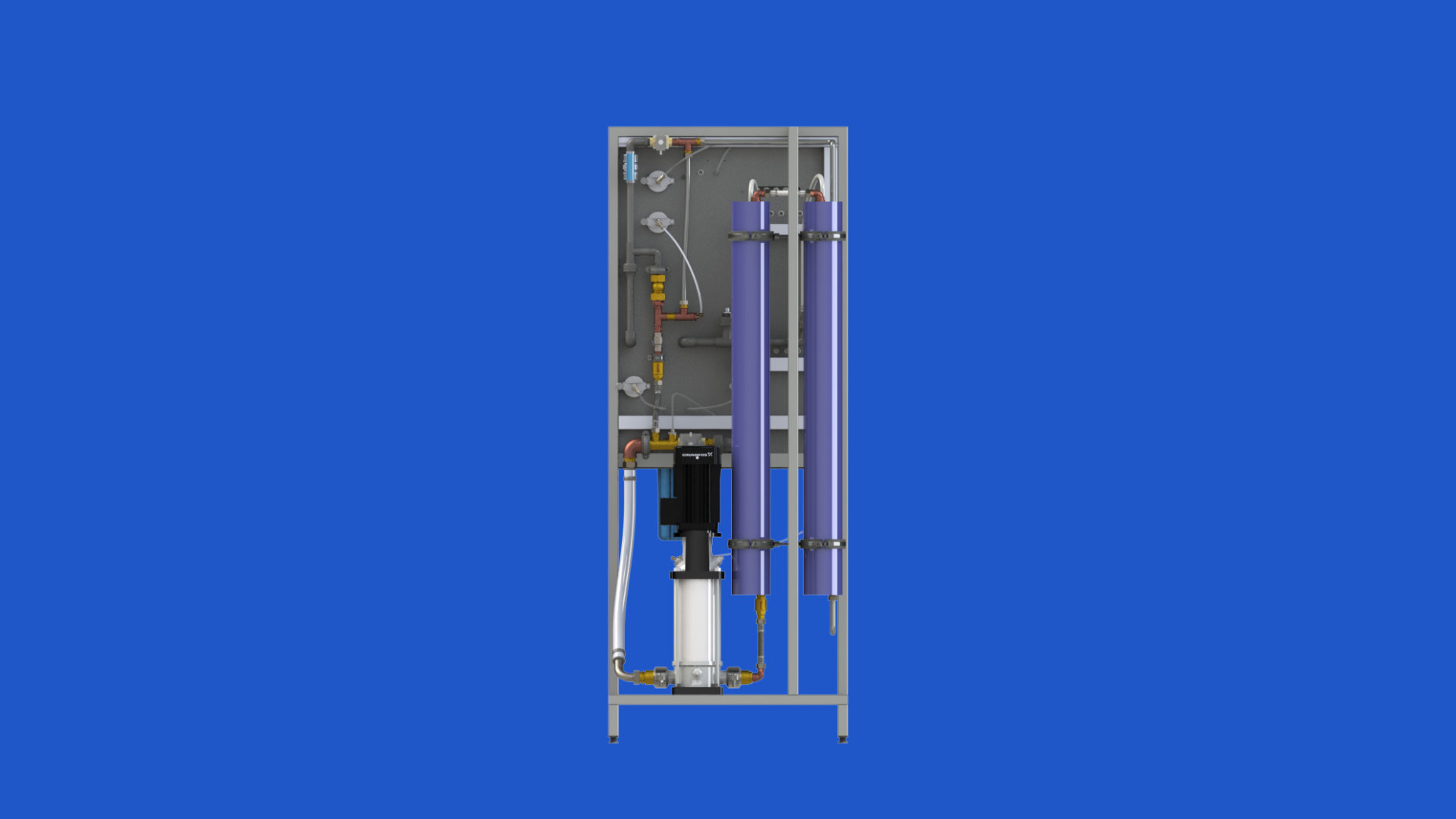

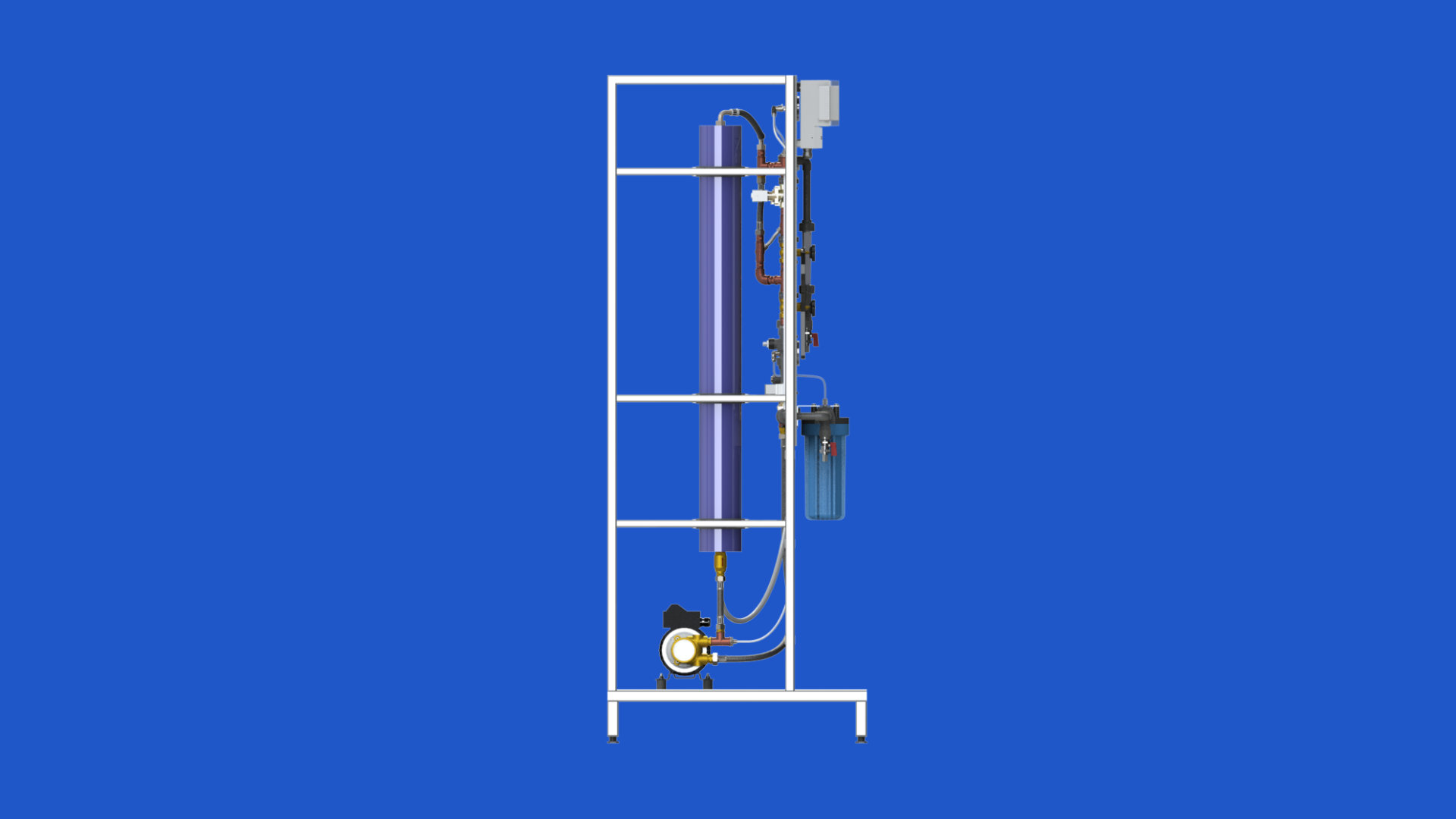

- 500 l/h – 1350 l/h

- Facelift for the UON-500 - UON-1350 series, which has proven itself over many years

Usage

The UON series reverse osmosis floor-standing systems are used to desalinate pretreated drinking water or well water to drinking water quality using the principle of reverse osmosis.

The systems are used wherever (partially) desalinated water (permeate) is required:

- Boiler feed water treatment

- Cooling water treatment

- Air conditioning technology

- Parts cleaning systems

- Sterilization tasks

- Commercial dishwashing technology

- Car washes

- Laboratories

Functionality

The desalination process in reverse osmosis systems is based on a membrane diffusion process in which pure water passes through a semi-permeable membrane under high pressure and salts, colloids, and other substances are retained by the membrane. The water fed into the reverse osmosis system is divided into a pure water volume flow (permeate) and a waste water volume flow (concentrate). The permeate is temporarily stored in unpressurized or pressurized water storage tanks to cover consumption peaks. The proportion of the concentrate flow fed to the wastewater must not fall below a certain minimum, as this can lead to deposits (scaling or fouling) on the membrane surface and a associated drop in system performance. To improve efficiency, the other portion of the concentrate flow rate is returned to the pump and passed through the membrane again together with the fresh water flow rate.

The reverse osmosis systems in the UON series are equipped with a microprocessor control system that controls and monitors all processes. Together with the appropriate accessories, the systems can be operated fully automatically.

Advantages

A pressure sensor for monitoring the inlet pressure increases operational safety and enables the reverse osmosis system to operate even at low flow pressures.

Laser-cut stainless steel mounting plate

Environmentally friendly process without the use of chemicals

Continuous permeate production

Fully automatic operation possible

Low operating and maintenance costs

Space-saving design

High-quality microprocessor control in industrial design with automatic flushing programs

Temperature-compensated conductivity measurement

Shutdown options when conductivity exceeds or falls below specified limits

Including flush solenoid valve

High-quality reverse osmosis modules

GfK pressure pipes with leak-proof connection technology

High-quality components (brand-name products)

Sampling valves for soft water and permeate

Permeate-side check valve

No plug-in fittings

Extensive range of accessories

Scope of delivery

Ready-to-connect, pre-assembled UON reverse osmosis system on a stainless steel frame for free-standing installation, consisting of:

Stainless steel frame with front panel made of laser-cut stainless steel sheet

Shut-off valve and pre-filter

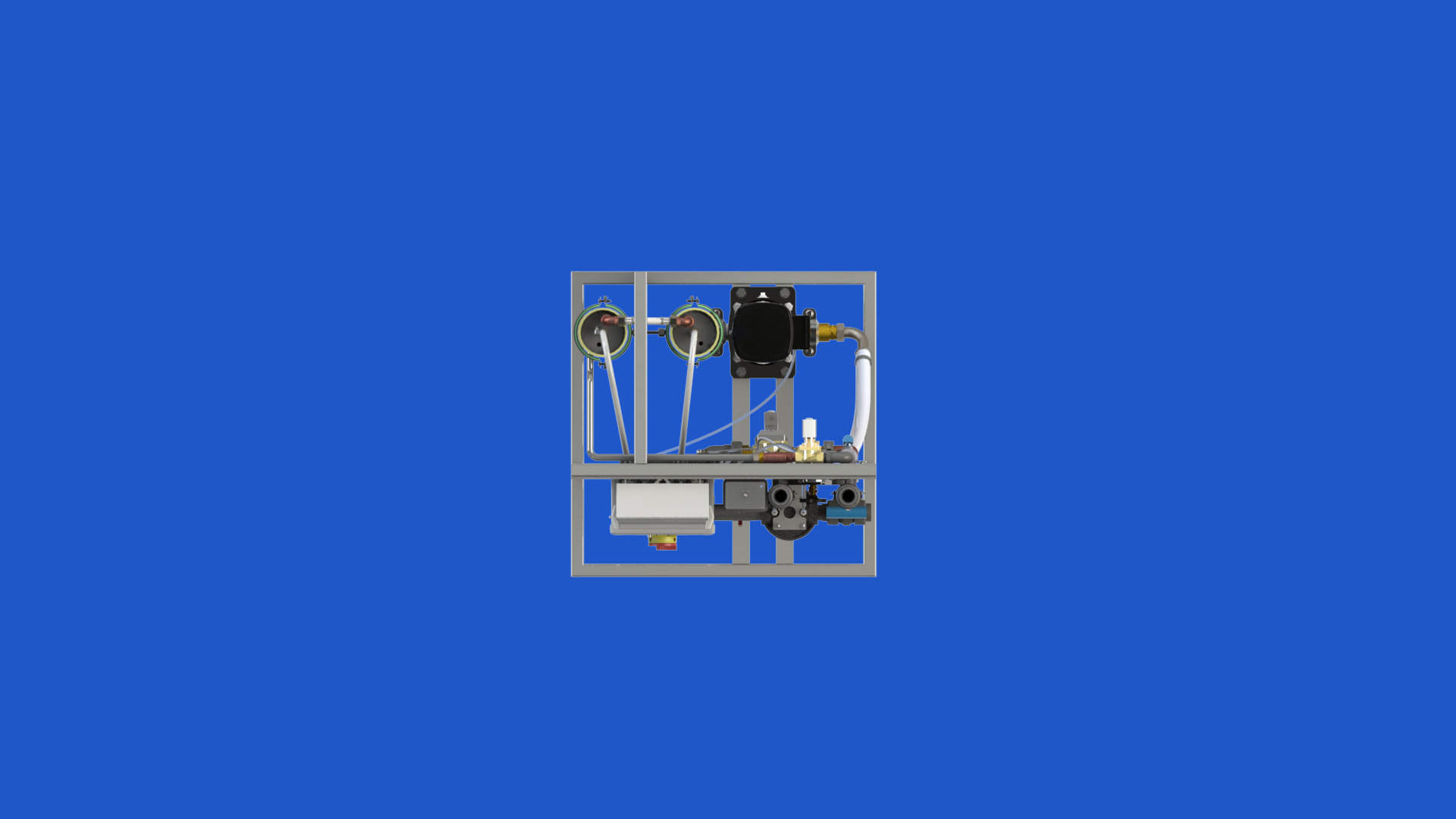

Inlet and control assembly with inlet solenoid valve, flush solenoid valve, control valves, pressure gauges

Float flow meter for easy control of the set volume flows

High-pressure pump as centrifugal pump in stainless steel design

Pressure switch for protection against pressure deficiency

Microprocessor control for semi-automatic or fully automatic operation, with plain text display, error history, conductivity measurement and monitoring, flushing program for concentrate displacement and interval flushing with adjustable flushing times

High-performance module in GRP pressure pipes with leak-proof connection technology

A pressure sensor for monitoring the inlet pressure increases operational safety and enables the reverse osmosis system to operate even at low flow pressures.