- Water meter controlled

- Capacity 50 to 600 cubic meters per day

Usage

The DWS1 series dual water softening systems are used to soften drinking water or well water to drinking water quality.

The systems are used wherever an uninterrupted supply of soft water must be ensured.

- Boiler feed water treatment

- Cooling water treatment

- For reverse osmosis systems

- Building technology

- Air conditioning technology

- Parts cleaning systems

- Flushing technology

- Car washes

Functionality

Softening is based on the principle of ion exchange (neutral exchange). Here, the hard water is passed through an ion exchanger material, which removes the hardness minerals calcium and magnesium and replaces them with an equivalent amount of sodium ions.

Once the ion exchanger has reached the end of its capacity, it must be regenerated. To do this, highly diluted brine is passed over the exhausted exchanger material. Due to the high excess of sodium ions in the brine, the aforementioned process is reversed: the exchanger stores sodium ions and releases the retained calcium and magnesium ions in return. These are flushed out as wastewater together with the rinse water.

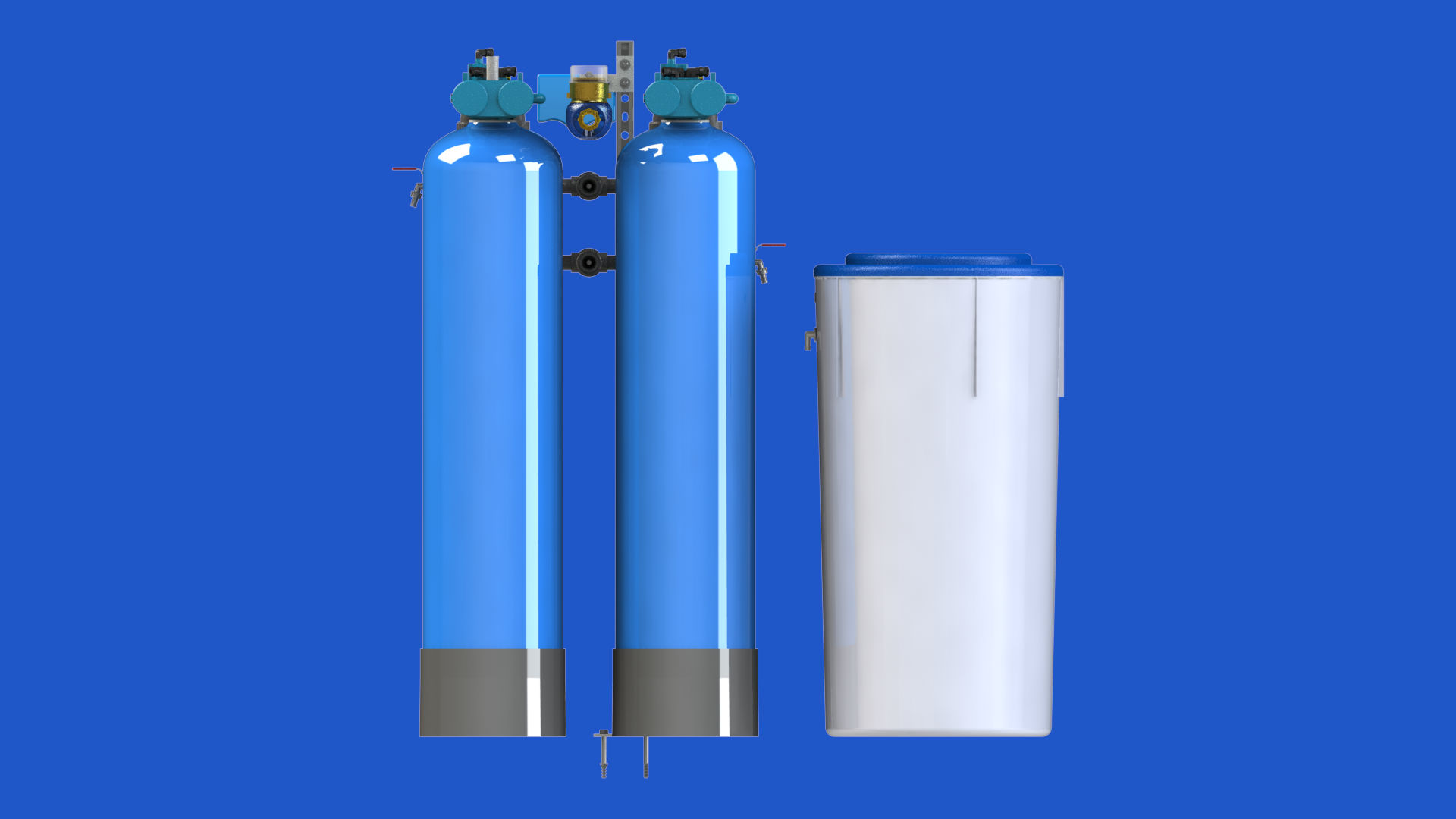

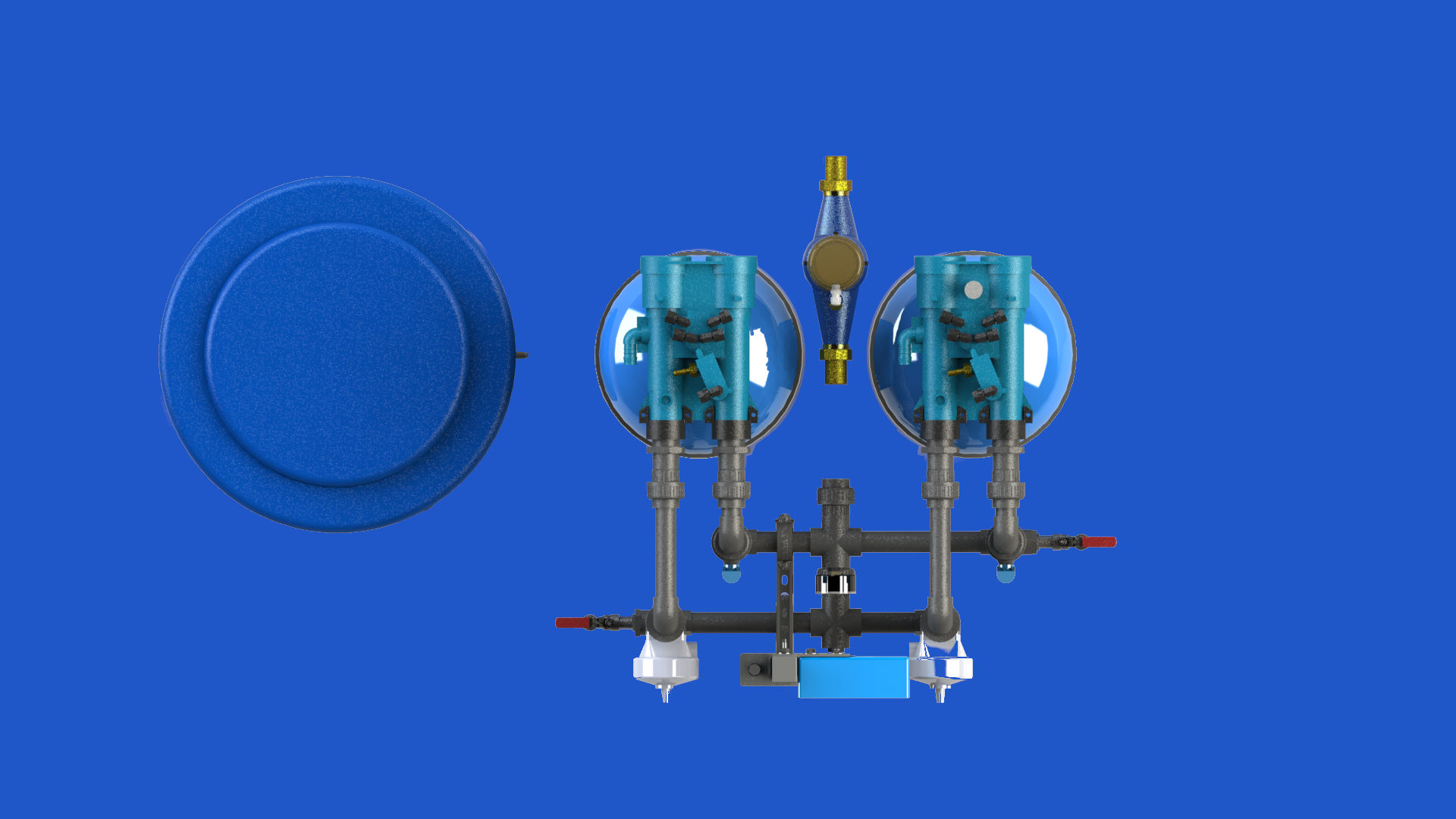

To ensure an uninterrupted supply of soft water, one of the two filter tanks is always in operation, while the second filter tank is either being regenerated or is ready for use after regeneration. The amount of soft water extracted is recorded by a turbine meter and transmitted to the control system. Once the capacity of the container in operation has been exhausted, the control system automatically switches to the container on standby. The exhausted filter container is then regenerated. A central control valve controls both the water flow through the containers and the regeneration phases:

- Backwashing

- Salting/Slow washing

- Washing out

- Refill salt dissolving container

Advantages

Control and operating valve for each filter container

Salt dissolving tank with sieve bottom for dry storage of regeneration salt and for precise determination of brine quantity

Two safety solenoid valves for safe removal and controlled refilling

Robust distribution system with nozzle star for optimal capacity utilization

Monosphere ion exchanger (brand name) in food grade quality

Continuous soft water production

Continuous soft water fully automatic operation production

Easy to use

Low maintenance and servicing requirements

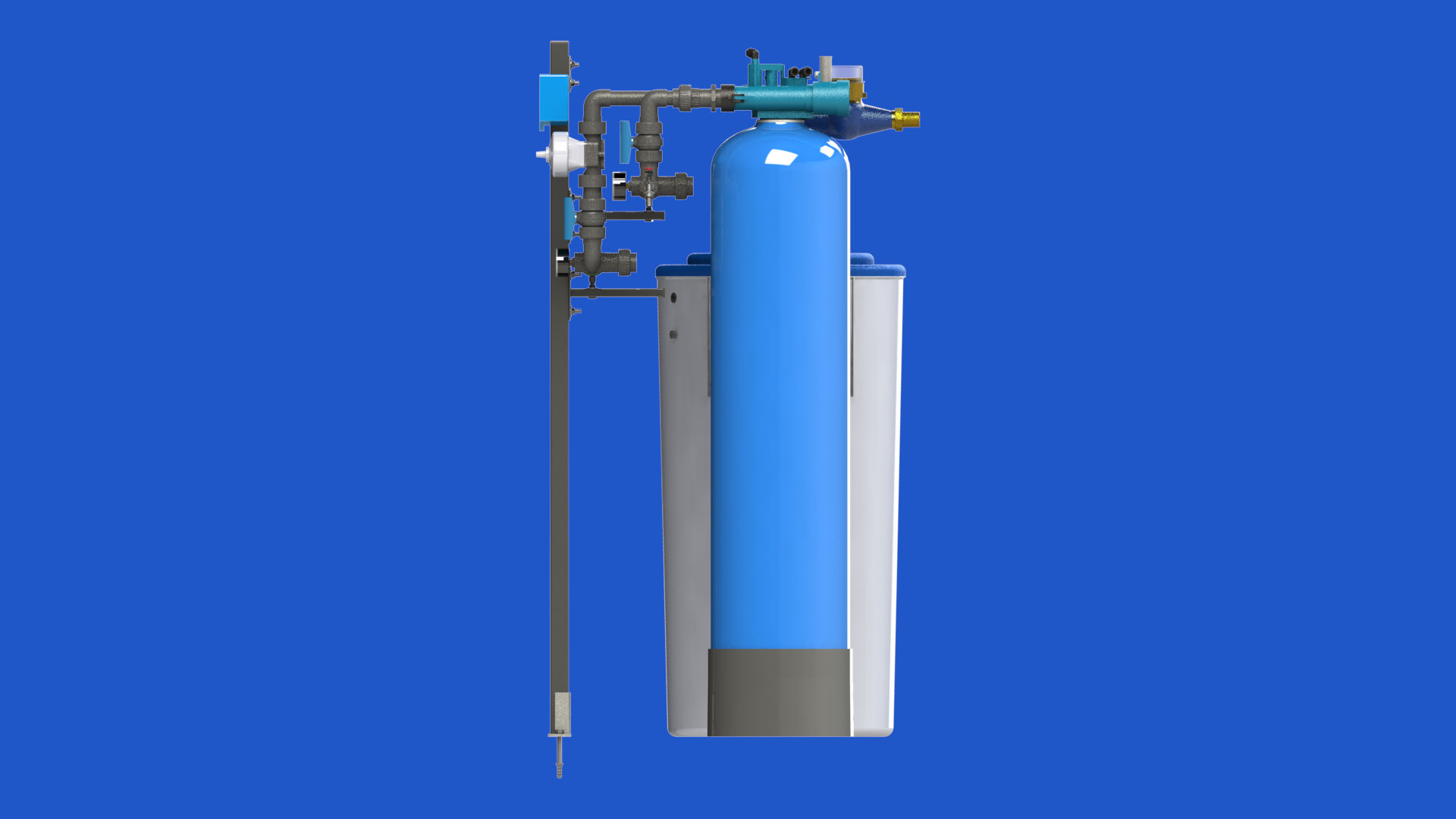

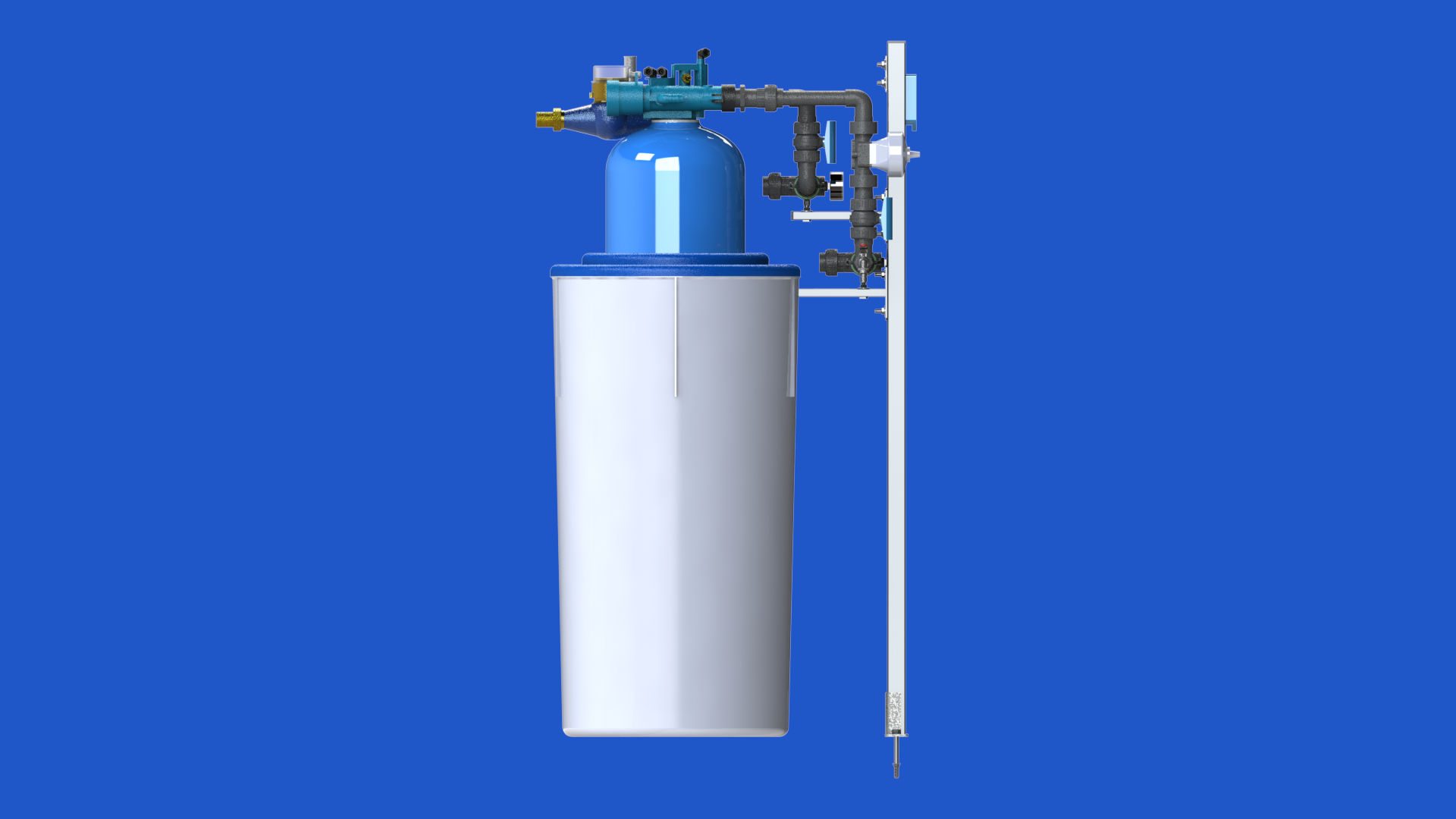

Space-saving design

Low operating costs

Simple control

Scope of delivery

Two filter containers made of glass fiber reinforced plastic, each filled with high-quality cation exchange material in food grade quality.

Two plastic control valves

PVC pipe set

Two operating valves

Contact water meter

Microprocessor control with rotary distributor

Salt dissolving tank with sieve bottom and two brine valves

Drain and brine hoses

Hardness testing equipment

Downloads

Catalog sheet

Download